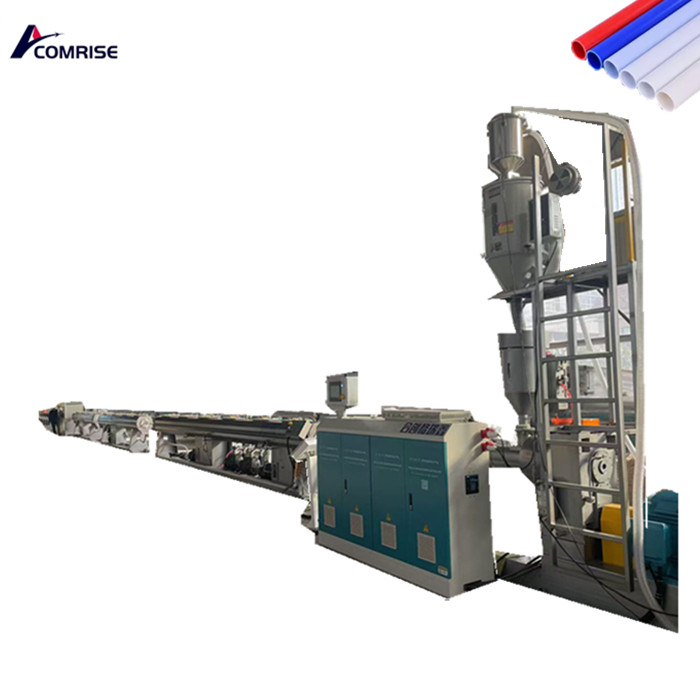

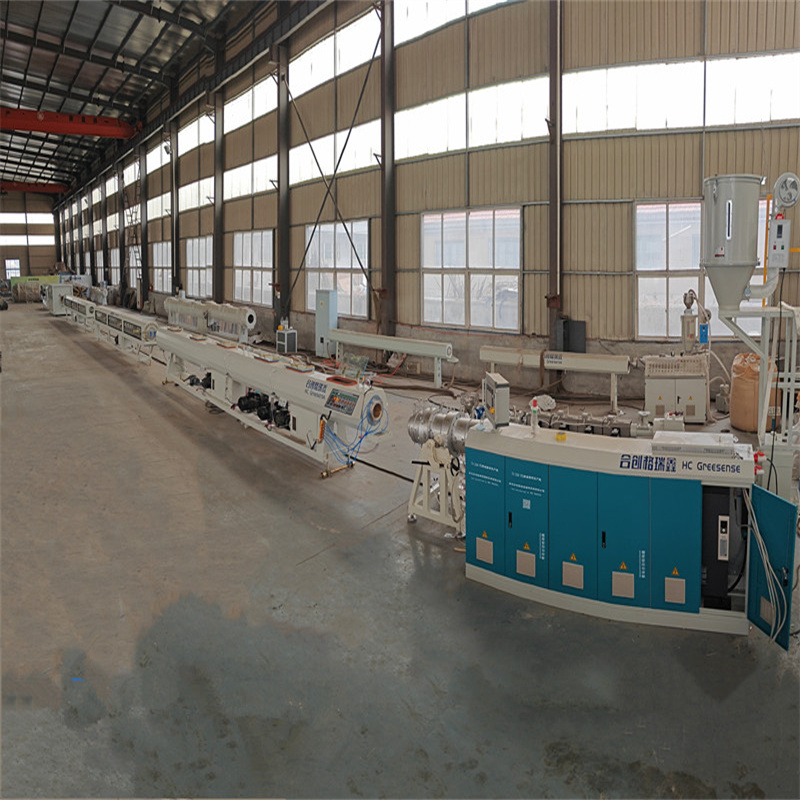

Linka pro vytlačování potrubí PPR

Odeslat dotaz

Key Components of a PPR Pipe Extrusion Line

1. Extruder:

- The heart of the production line, where PPR raw material is melted and extruded into a pipe shape.

- Equipped with a screw and barrel designed for PPR material processing.

2. Die Head:

- Shapes the molten PPR material into the desired pipe diameter and wall thickness.

- Customizable for different pipe sizes (e.g., 16mm to 110mm).

3. Vacuum Calibration Tank:

- Cools and calibrates the extruded pipe to ensure precise dimensions and a smooth surface finish.

- Uses a vacuum system to maintain the pipe's shape during cooling.

4. Cooling Tank:

- Further cools the pipe to solidify it completely.

- Typically consists of multiple water baths to ensure uniform cooling.

5. Haul-off Unit:

- Pulls the pipe at a controlled speed to ensure consistent production and proper wall thickness.

- Equipped with belts or tracks to grip the pipe gently.

6. Cutter:

- Cuts the pipe into specific lengths (e.g., 4m or 6m) automatically.

- Can be programmed for different cutting lengths.

7. Stacker:

- Collects and organizes the finished pipes for packaging or storage.

- Can be manual or automatic, depending on the production line's sophistication.

---

Types of PPR Pipes Produced

1. Single-Layer PPR Pipes:

- Made from a single layer of PPR material.

- Suitable for general-purpose applications like cold and hot water systems.

2. Three-Layer PPR Pipes:

- Consist of an inner layer, an adhesive layer, and an outer layer.

- Offers enhanced properties such as higher pressure resistance, better insulation, and improved durability.

GET A QUOTATION NOW